Serialization Allows Data Linking To Individual Items

AMACENA-BI supports serialization, in other words AMACENA-BI allows assigning technical and operational data to each individual produces/processed item. This is highly beneficial in case of analyzing quality issues as it allows to reconstructing the respective ambient situation which lead to the observed issue. Significant savings occur in cases that such error happens again as the reanalysis of the issue is not necessary.

Business intelligence down to item level

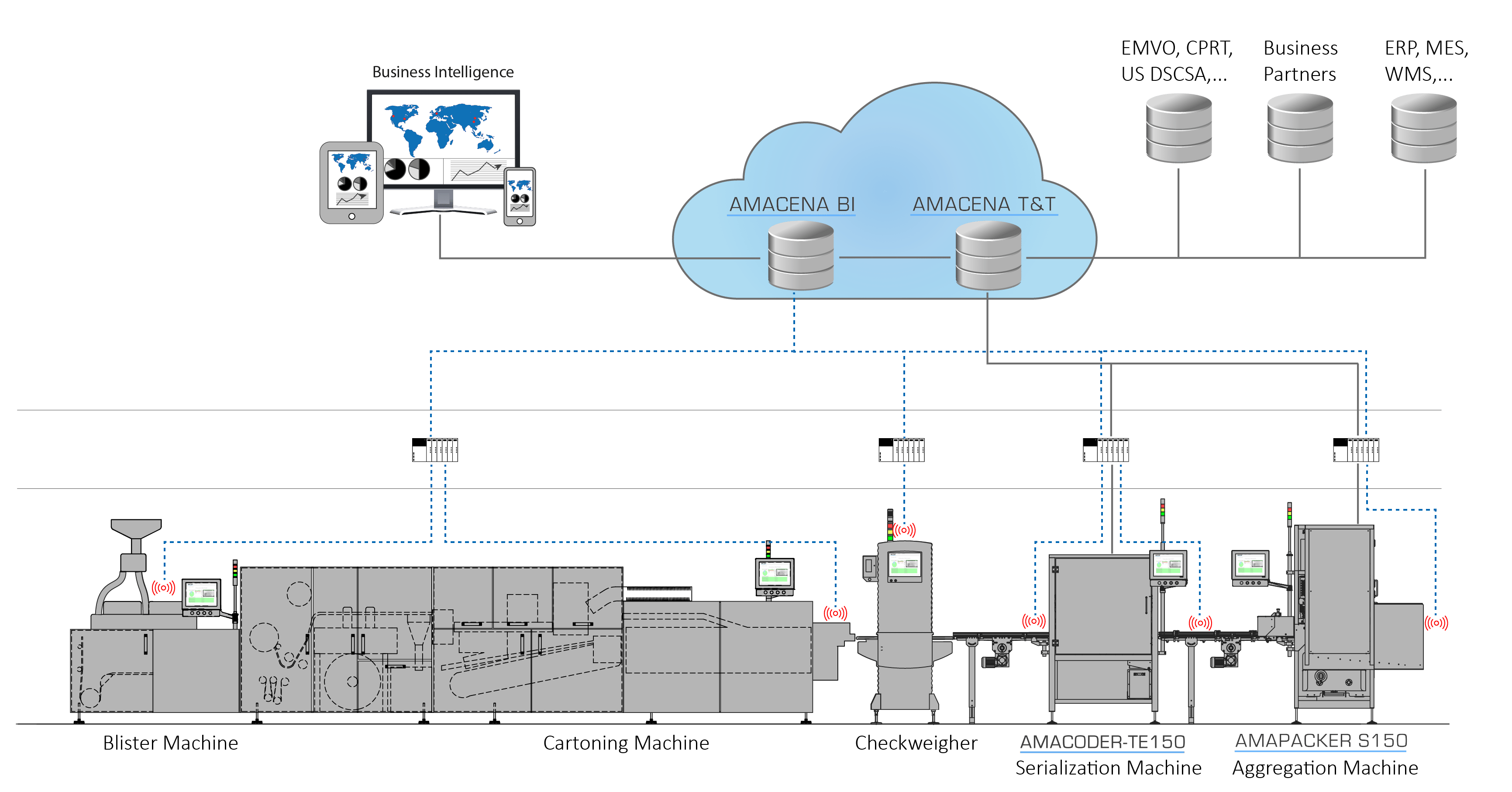

Business Intelligence is the disruptive technology, allowing maximizing “Overall Equipment Effectiveness” by in-line collection and monitoring line “Availability”, “Performance” and “Quality”. The analysis of this information leads to minimizing line interrupts, production issues and reject rates for lifting OEE to a higher level. For demanding products, process data should be assigned according “Industry 4.0” philosophy to each individual item, called serialization to allow individual history reports. Serialized products are, a prerequisite for next generation BI systems. Hicof AMACENA is the breakthrough solution for a fully compliant Industry 4.0 solution. The integrated serialization and BI software suite is cloud based to master complex functionalities and big data volumes through a no SQL infrastructure.

AMACENA BI HIGHLIGHTS

AMACENA BI is fully integrated in all Hicof Machines to allow to easily enter the world of Industry 4.0. AMACENA BI offers you the tools to collect data across you production lines, either from Hicof machines or 3rd party brands, to collect and analyze technical and operational data in various ways. Thereby, AMACENA BI allows to merge data coming from the serialization process with the KPI’s coming from AMACENA BI which opens new possibilities in optimizing the production process.

The unique selling propositions of AMACENA BI are:

- Extensive data analysis features from easy Output Flow managment to OEE up to Video analysis and Serial data linkage

- Plug and play integration with Hicof Equipment

- Easy integration of non Hicof Equipment via Data collection terminals for minimal invasive system integration (no PLC changes, no Software changes)

- Worldwide access to all data via web-browser to the high performance noSQL Database

- All software updates for the Cloud software are free of charge

AMACENA BI Connector boxes allow quick and easy installation on any machine without changing existing hardware or Software (non-invasive).

AMACENA T&T manages all data related to the track and trace process and is fully connected to AMACENA BI

AMACENA BI allows to observe all production data in real time to generate relevant business intelligence.

Hicof Machinery can directly communicate with AMACENA T&T and AMACENA BI without the need of local server infrastructures.

All AMACENA management tools can be accessed via any end-user device from around the globe at any time

AMACENA BI can read analogue sensor data as e.g. temperature data from a blistering tool

AMACENA BI relies on digital counters across the whole production line to build the data used for business intelligence (e.g. Predictive maintenance, OEE, Videos,...)

Serialization: Compliance is mandatory, however what’s about saving cost?

In many industries, as e.g. in the pharmaceutical and tobacco industry, serialization is or will be a legal requirement. Once serialization is implemented, the question rise: What is its benefit beside compliance to regulatory requirements? The answer is simple, just make the next step: Add “Business Intelligence” by collecting operational data of your manufacturing equipment, analyze these data and improve your “Overall Equipment Effectiveness” OEE to unanticipated heights. Combining serialization with business intelligence allows generating history records of individual Items/ products, mandatory for long term quality improvements, issue solving, anti-counterfeiting and warranty management. AMACENA by Hicof offers a scaleable solution, combining the two autonomous modules, Serialization and Business Intelligence into one integrated Industry 4.0 suite.

AMACENA-BI data visualization and dashboard for your smart factory

The software is a powerful and flexible management tool, allowing to process and visualize in real-time collected data and generate correlations between them. The data analysis can be enhanced by using mathematical tools to take conclusions for immediate action. Additionally, BI-based preventive line maintenance increases up-time and saves money. Interfaces to other business software or to PLCs via OPC is integrated. Supported mobile devices (smartphones and tablets) allow on-location, performance monitoring and real-time issue management directly on the line. Cloud technology permit using AMACENA BI data management over many locations without the need of local server infrastructures.

Output Flow

OEE

Predictive Maintenance

Maintenance Timer:

Video Stream

AMACENA BI Analysis Tools

Hicof AMACENA BI features a multitude of tools and capabilities following a few highlights are picked:

- Basic Output Flow Analysis allows to see the status of the production line at any time live in a dashboard

- Hicof AMACENA BI features OEE Analysis which allows to evaluate the Overall Effectiveness of the production based on industry standards. The KPI’s can be displayed on easily readable live dashboards. Thereby, the tool can be set to trigger alarms in case goals are not met.

- Hicof AMACENA BI features Predictive maintenance tools by monitoring counters or timers based on custom rule sets based on the process peculiarity.

- Hicof AMACENA BI can link all data to video streams coming from the production line for in depth root cause analysis of potential issues.

industry 4.0 Data collection Hardware

Hicof can offer Data Collection Hardware to easily integrate any 3rd party machine or sensor into the AMACENA BI software environment. The devices run autonomously and can directly upload data to AMACENA BI. The devices come from two sensor inputs up to much higher counts for complex machinery. The data collection devices can read digital and analog sensor signals in very high frequency.

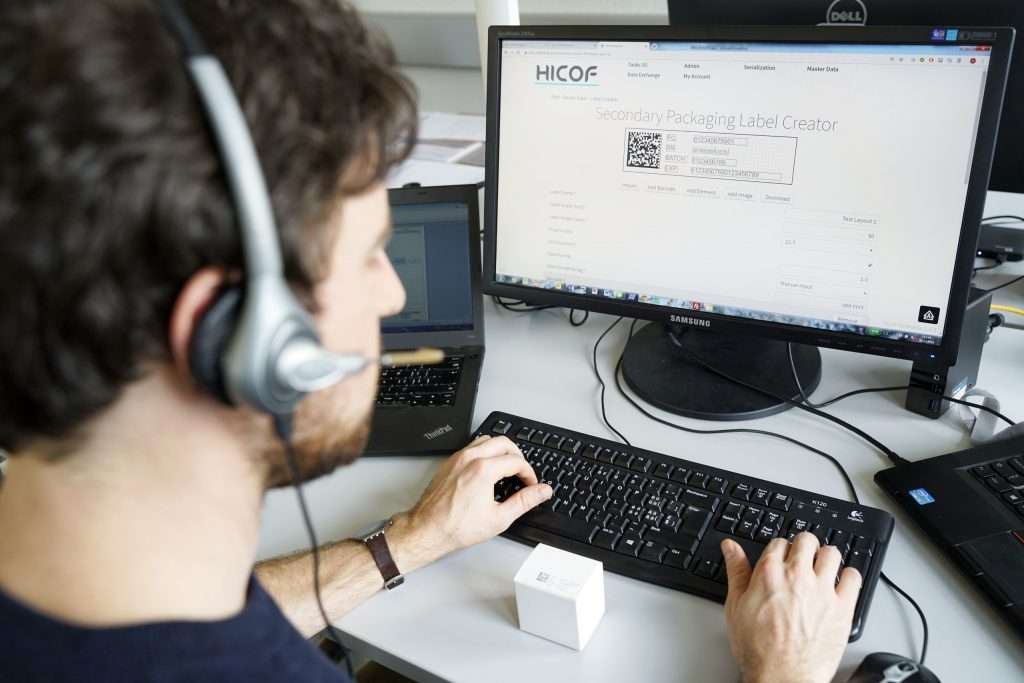

SUPPORT

The AMACENA system is a fully integrated IT-backbone, starting at machine level from the devices as printers, cameras and sensors up to data interfaces of governmental servers. In case of an issue, our experts have instantaneously access through remote access to all relevant parameters across all IT-servers down to the PLC, allowing a seamless and immediate support. This is the opposite of the conventional ISA-95 environment with several software and machine suppliers in which each service engineer has only access to his fraction of data, making a comprehensive root cause analysis extremely cumbersome as he has to synchronize with other involved vendors.

Hicof solves the issue by offering One System, One Supplier, One Responsibility!