The Objective

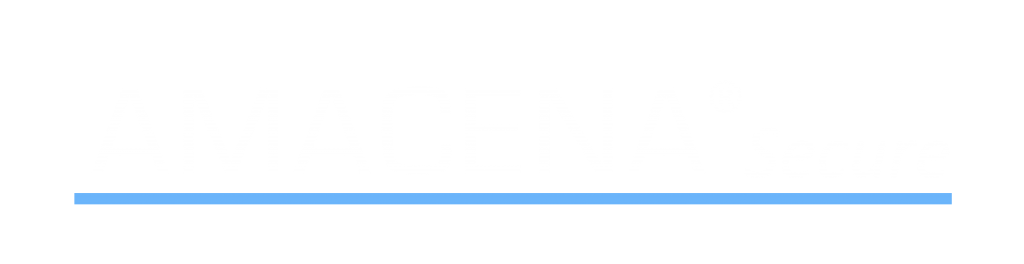

The Hicof AMACENA database is a powerful, full stack, industrial Track- and Trace database. It supports all relevant business processes and includes the security functions required to manage serialized products in an industrial environment. AMACENA is a powerful tool to fight e.g. against:

- Diversion, Grey Markets

- Contraband, Smuggeling

- Excise Tax Fraud

- Sales of stolen originals

For product tracing, 2D Barcodes according ISO standard (QR & Data Matrix) must be used to allow comprehensive scanning in the supply chain.

Unfortunately, fraudulent copying of such codes is easy which limits their achievable security. The solution to eliminate this shortcoming is our innovative, patented AMACENA Secure Serialization for Security Printing solution. To prevent criminal counterfeiting of tracing codes, the AMACENA Secure System integrates in its tracing code a digital security feature which allows easy authentication of the code originality (e.g. by smartphone) and cannot be copied.

Serialization for Security Printing

Amacena Secure offers a unique, patent protected solution to combine standard serialization capabilities with authentication technology. This allows to close the security gaps in the serialization infrastructure to fight criminal manipulations of all kind in the supply chain.

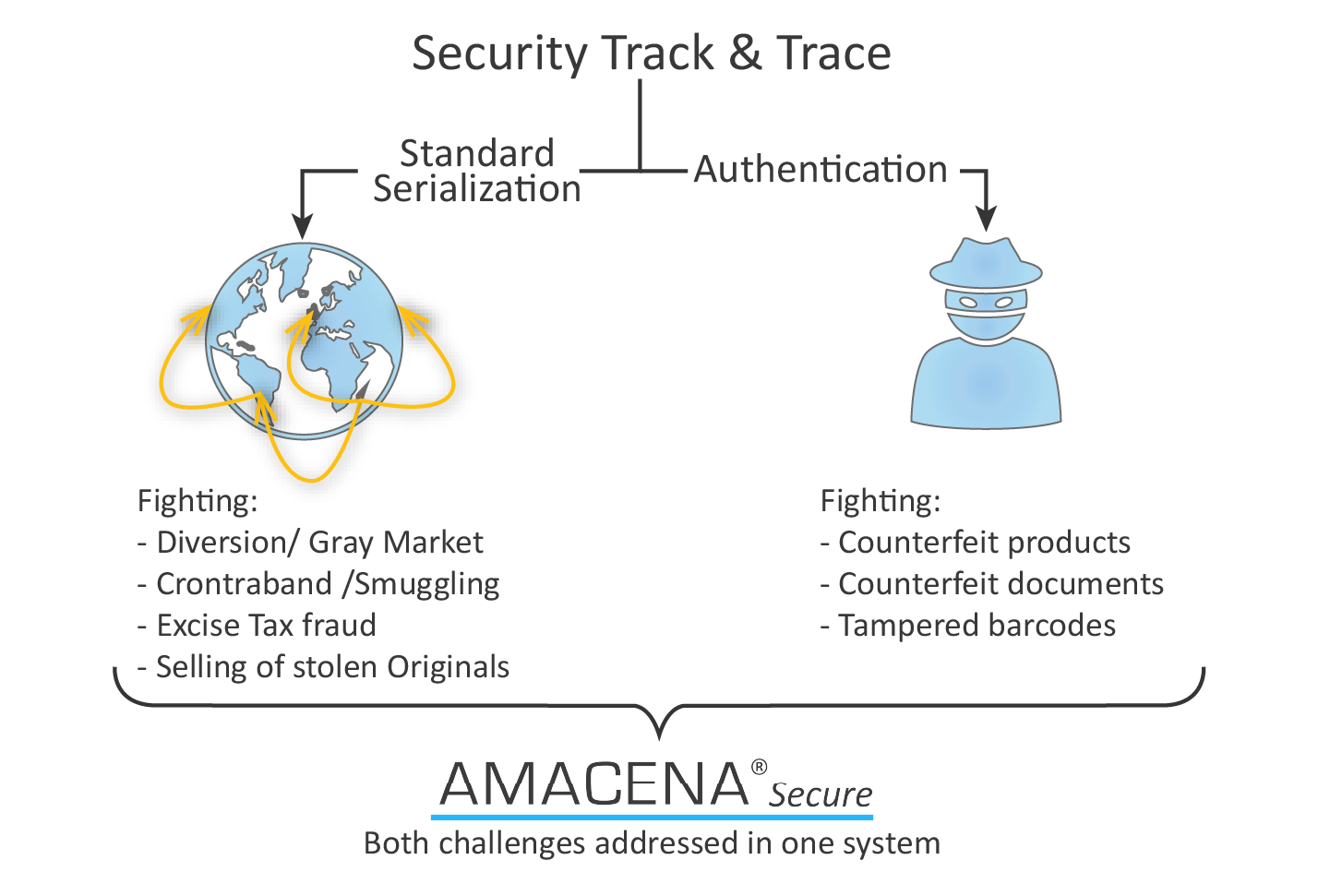

To achieve that Amacena Secure is base on the proven AMACENA T&T Databasewhich can be scaled-up to trillions of serial codes per year. Additionally, AMACENA Secure integrates an additional hidden security information into printed Barcodes that are used to authenticate the originality of the serial code.

The mentioned authentication information into the AMACENA Secure code has no negative impact on the code quality which remains fully compliant to the barcode quality assessment ISO/IEC standard 15415 as well as the basic barcode specification according ISO/IEC 16022 standard that is worldwide applicable and used by millions of reading and printing devices as for example hand-scanners or industrial cameras. All these devices are able to access the overt serial data that is stored in the database.

The embedded covert authentication information is generated by a rationale which changes from code to code, triggered by the serial number. Reverse engineering is therefore almost impossible. This information can easily be read by a smartphone app or other industrial devices and allows identifying if a product is original or copied as the hidden information will be lost in case of a reproduction attempt.

The AMACENA Secure, specifically developed for Security Printing Companies, is data wise very lightweight and allows managing serial data in extremely large quantities at competitive cost. Printing the serial barcodes is possible with printers starting at 200 dpi resolution which ensures the cost effectiveness of the technology.

Overall, AMACENA Secure is the next generation technology for security applications that are running in large quantities at competitive cost.

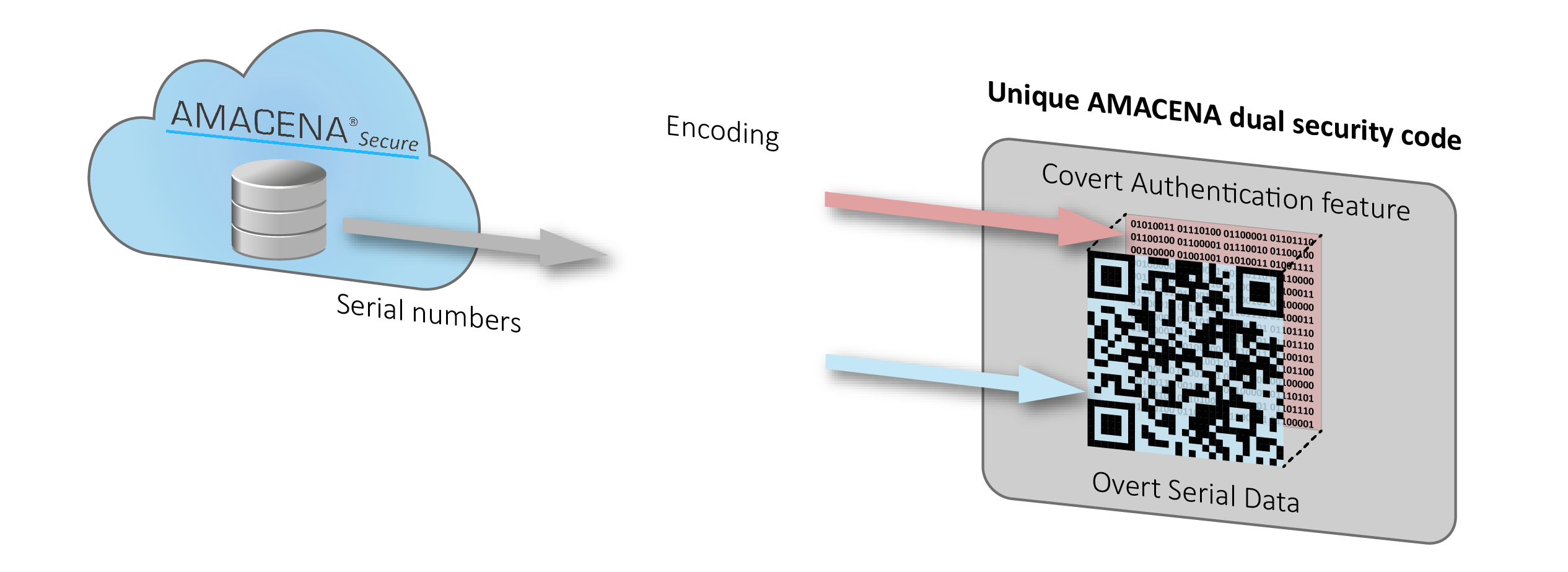

Unique Secure Workflow

In the security industry, not only the data carrier must be secure. As consequence, the architecture of AMACENA Secure includes specific processes, tailored to comply with the needs of the security Security Printing industry.

In common databases, manual change of data, e.g. master data are processed by a single person which is an error prone process. Therefore, for systems, in which sensitive information are managed, manual data change processes require a higher sophisticated change process. Best practice to prevent issues is a four-eye process, integrated in AMACENA Secure which allows dividing the change process between a data owner and the Approver. The process follows the following steps:

- Copy of the existing dataset to a draft version by the data owner

- Data adoption by the data owner (with possibility of saving the intermediate state)

- Approval of the finalized Draft version

- Replacement of the current data release with the newly released dataset

This process highly improves the security of data changes while allowing to keep track and records of all changes in the system for auditing purposes. As the process is being build into the solution, no extra work is required to track data changes via a paper-based documentation anymore.

THE LABEL CREATOR

Hicof AMACENA Serialization Software features a build-in web based label creator to create and adjust all print layouts for AMACODERS, and all connected tertiary label printers. The label creator allows GMP compliant change control of all label parameters across the enterprise.